1. Intro

Why this project? I wanna build a robot from scratch to fill the gap between theory and reality.

To build the robot, usually need following knowledge base

- Mechanics, the build the body of robot

- Electronic, the power of the robot

- Computer, the brain of the robot

2. Goal

For the robot, I would like to focus on the mobile robot platform

Two level goals:

- Basic level, the robot can move, and use the lidar as a SLAM sensor, can track something using camera

- More precise control, going from A to B, the error should be less than 1cm

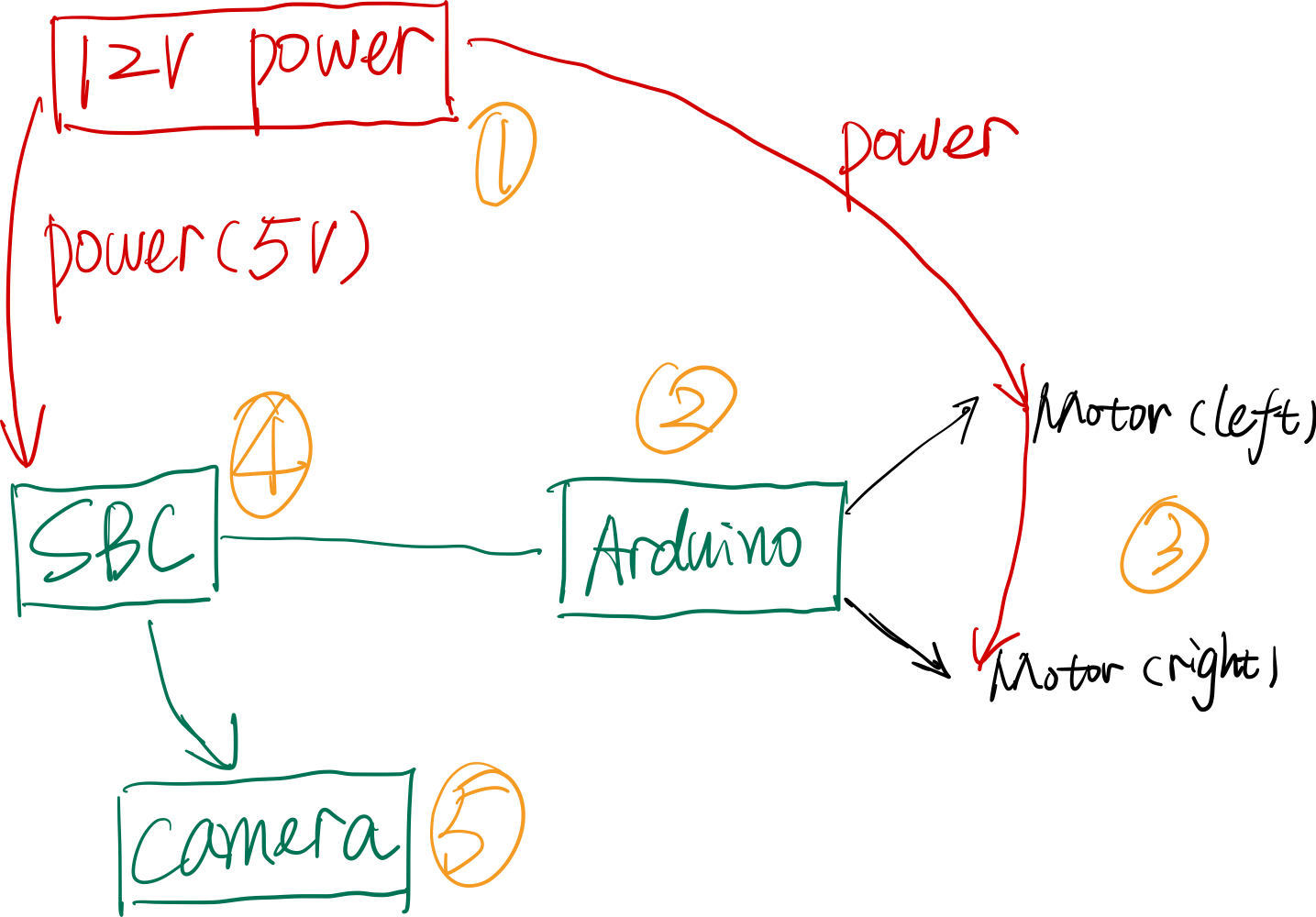

Consider a layer platform

- Environment sensing, different sensor to be used, a SBC is used. LiDAR, video camera, speaker, microphone

- Intelligence, communication, SBC, control other part

- Navigation, get the high-level command and go to desired position

Communication Ethernet

3. Path

Motor

- Control how it works

- feedback control

- position control

- speed control

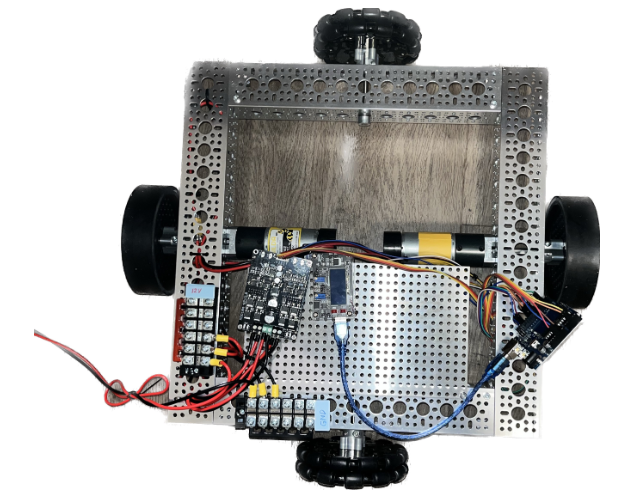

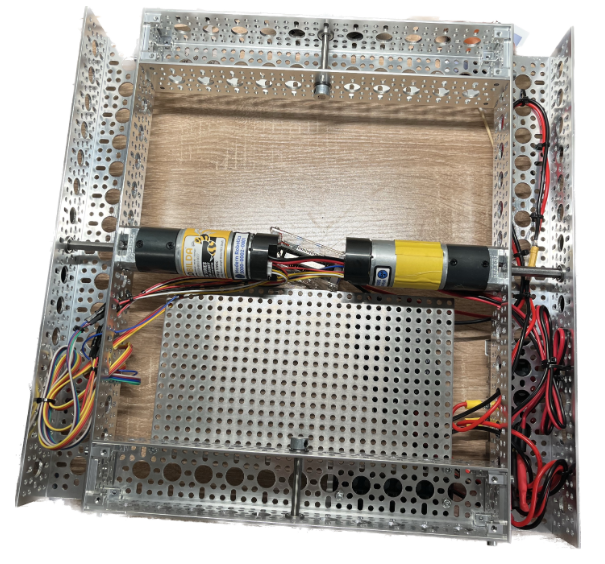

4. Chassis

Design

34cm 30cm 23cm

Front x2

Rear x2

5. New Thing

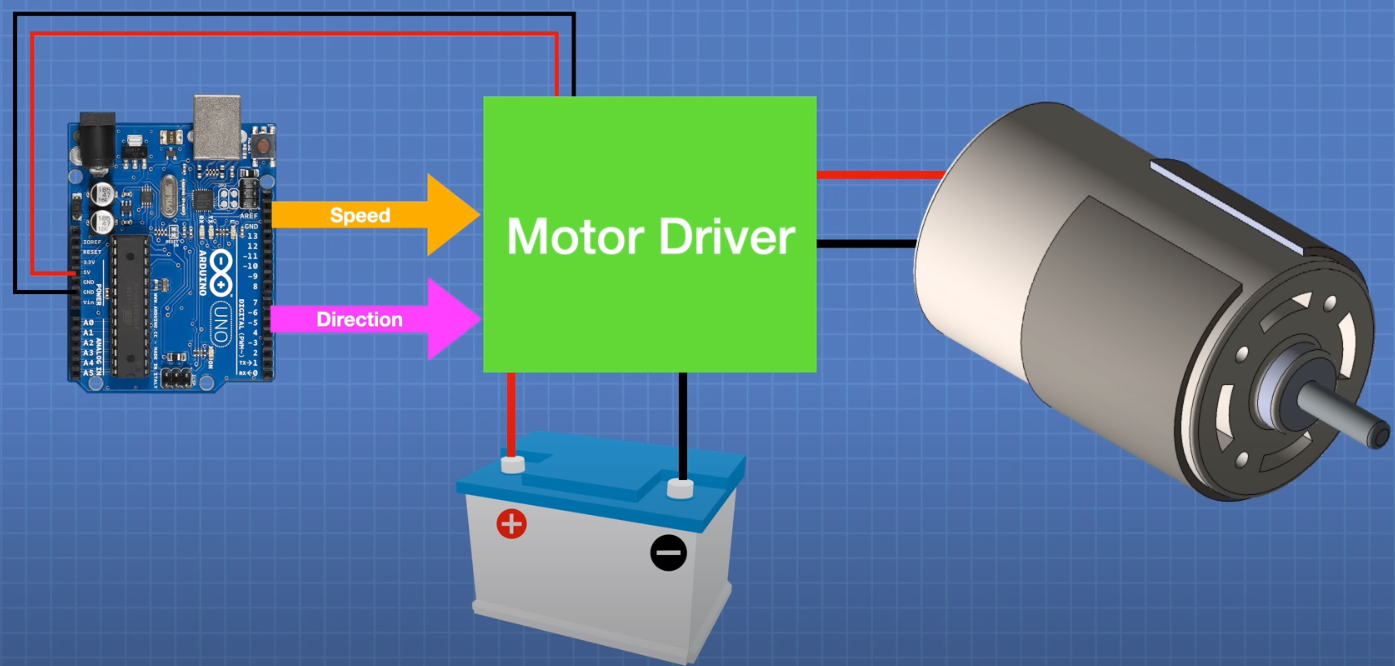

5.1. Motor Driver

Working with DC motor

- Direction

- Using the H-bridge could change the direction of voltage and current

- MOSFET would drop a little voltage

- Speed

- PWM

L298N, simple, classic but too old

More improved design:

- TB6612FNG, improved version of L298N

- DRV8871, if you only need a SINGLE motor to drive

- MX1508, small, but not soldering friendly

Driver that can handle large current:

- DBH-12,20A, peak 30A

- IBT2, single channel, 30A, peak 43A

5.2. Micro Controller

UNO or raspberry pi PICO

Pico should be a better choice in 2022 (introduced in 2021)

- Much faster (133MHz vs 16MHz)

- Much larger RAM

- Lower power DC (1.8v-5.5v)

- More port (Analog and Digital)

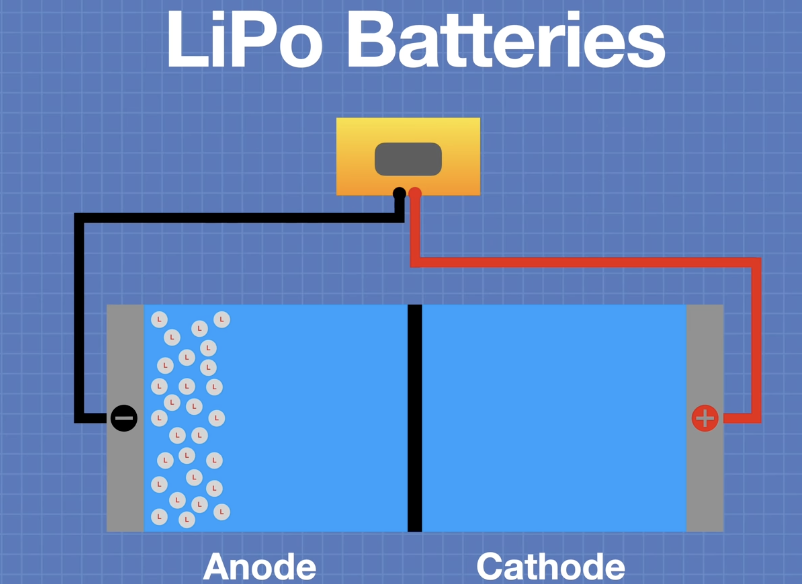

5.3. Battery

LIPO battery, high capacity in lightweight

Con: easily damaged

Lithium-Ion Polymer (锂离子聚合物电池)

- Application where weight matters

Each cell can provide 3.7V

- Fully charged 4.4V

- Minimum safe charge is 3.0V

Different wire

- S- serial

- P- Parallel

Capacity

- C rating

Connection:

- Dean

- XT60

- EC3

5.4. Base Material

Consider: strength to weight

Aluminum

- lightweight

Acrylic (亚克力)

- lightweight

- drilled

5.5. Channeling System

Actobotics system: good availablity

GoBilda system: good quality, successor to the Actobotics

Vex system

Lynxmotion

5.6. Motor Selection

DC Gear motor

- Planetary: a bit expensive, but quiet

- Spur: cheap, but noise

Things to consider

Nominal voltage, optimal voltage

No Load RPM, when nothing connected, what is the RPM

Stall torque and current. Newton Meter

Stall: no more move

<30% stall point

Size and shaft

Mount

Shaft may not in the center

Encoder is important

We need to first determine the

- Weight (Load)

- Speed

- Longest working area for the robot

- The robot should be slower than human walking (safe to control the robot)

Calculate the required specification for the motor and battery

Motor, hub, bearing, encoder

- Bearing is quite important since the whole load is on the wheel

- if there are no bearings, the motor would load all the pressure

5.7. Wheel

Parameter for wheel:

- Wheel size, determine the speed

- Wheel width, determine the traction and maximum load

- Wheel traction, determine the surface robot can travel

- Wheel type, determine the degree of movement

Type

- Standard, most common, wide range size, can be used as driver or idler

- two degree (forward and backward)

- Caster and Ball wheel, orientable, use as idler, most used for indoor design

- Mecanum, different left and right wheels, multi-drirectional, 45 degree roller

- Omni wheels, 90 degree roller, 4 degree of freedom, best for indoor

Arrangement

Durometer

- harder or softer?

- 30A maybe too soft

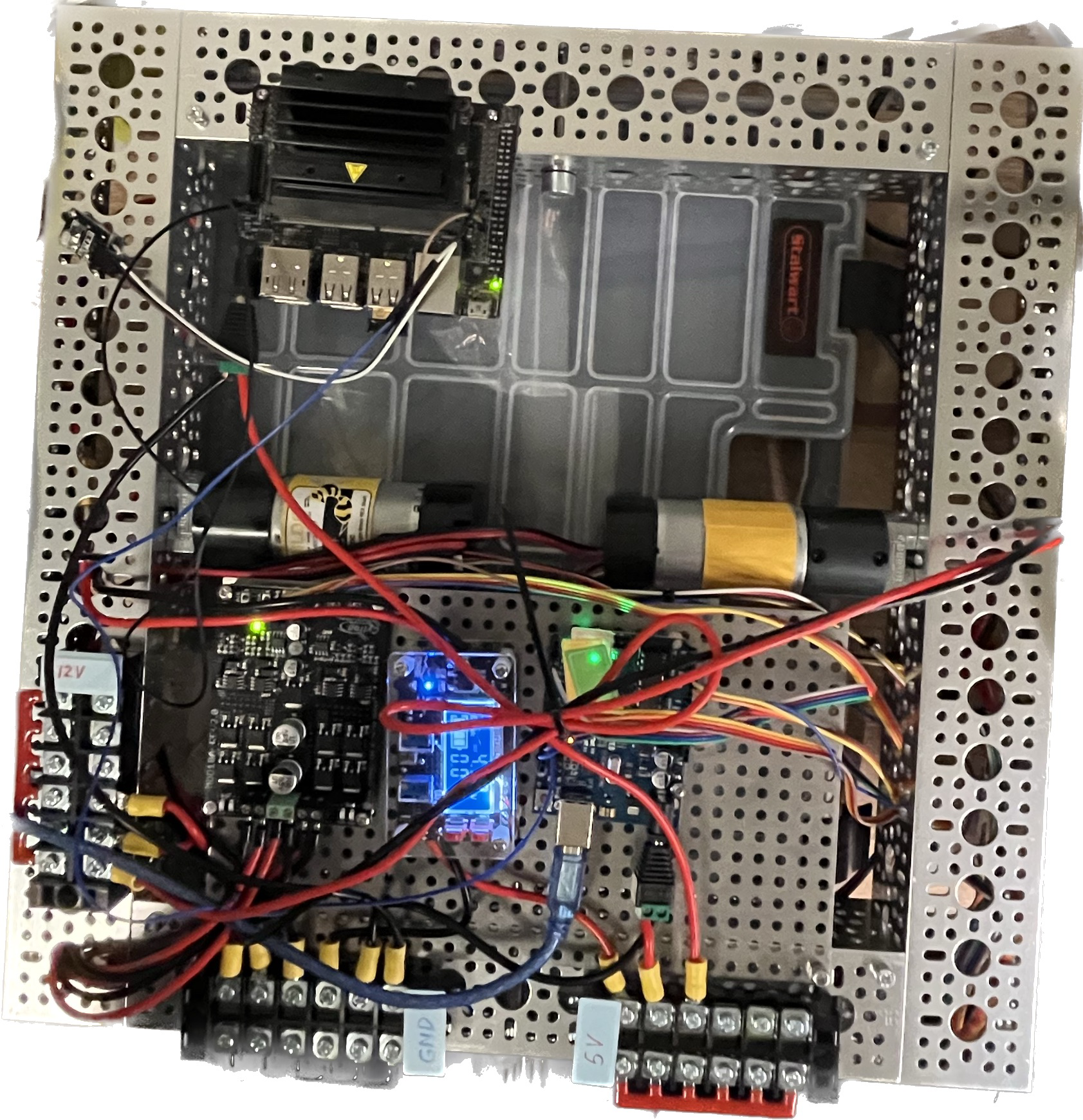

5.8. Electronics

Motor driving

Power distribution board

Motor controller

Fuses: (保险丝)

- if the current is too big, would case heat, may lead fire

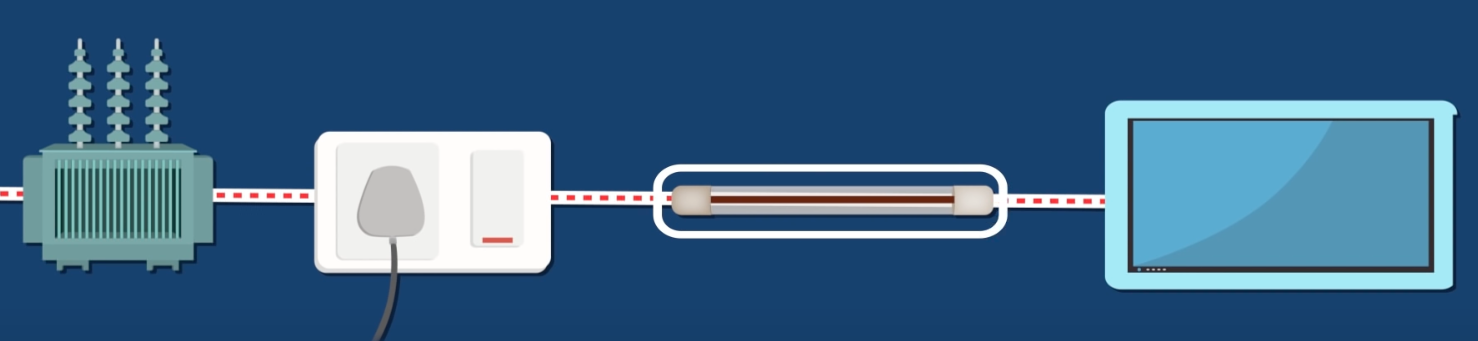

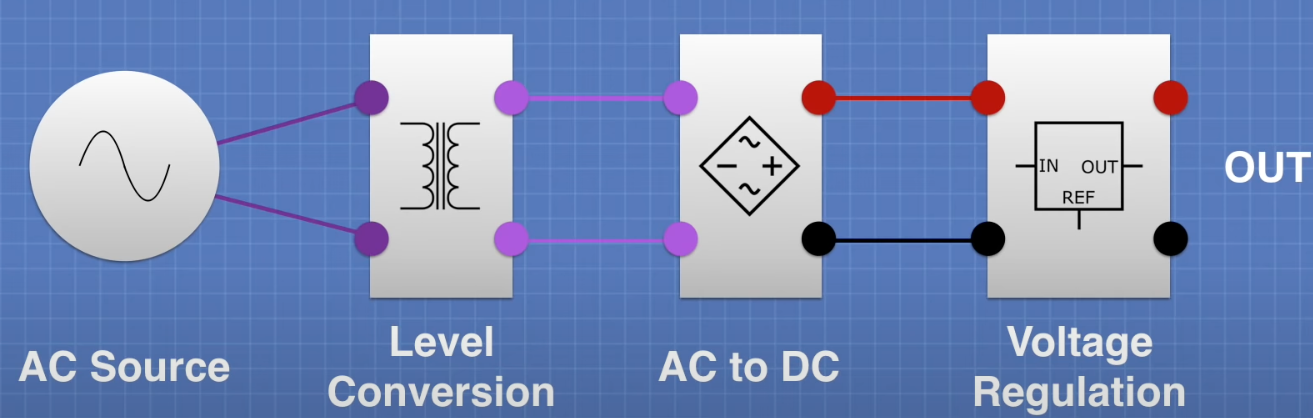

5.9. Power Source

Regulator and Convertor

Logic voltage, 5V(4.7-5.2), 3.3V.

Motor: 6V, 12V

AC:

DC:

- From high to low:

- voltage regulation,AMS1117-5(much lower voltage drop), 1A

- buck converter, high-efficient, mini360

- From low to high

- boost converter, PSM205, to a usb

- From any to any

- Buck boost converter, S9V11F5 (from 2-16 to 5)

5.10. Motor Controller

5.11. Weight Consideration

If the robot is too lightweight, there would be not enough traction for the robot to move.

5.12. Connector

JST

6. BOM

| Part | Name | Num | Check |

|---|---|---|---|

| Front wheel | Motor | 2 | 1 |

| Front wheel | 120mm Wheel | 2 | 1 |

| Front wheel | 8mm REX bearing | 2 | 1 |

| Front wheel | 8mm Face bearing | 2 | 1 |

| Front wheel | 8mm shim | 4 | 1 |

| Front wheel | m4 washer | 8 | 1 |

| Front wheel | Hyper Hub | 2 | 1 |

| Front wheel | 12mm M4 screw | 8 | 1 |

| Front wheel | 18mm M4 screw | 8 | 1 |

6.1. Omni wheel

| Name | Num | Check |

|---|---|---|

| Omni wheels | 4 | 1 |

| Spacer 4mm | 2 | 1 |

| 6mm D shaft hub | 2 | 1 |

| 6mm D shaft bearing | 4 | 1 |

| 6mm Collar | 2 | 1 |

| 30mm M4 screw | 8 | 1 |

| 80mm 6mm D-shaft | 2 | 1 |

7. Progress

11.21

12.5 Test Robot Motor

- Full Speed

- Arduino PWM

- 20%

- 50%

- 100%

- Encoder

- Each rotation

TODO:

- Add a ferrule crimping tool kit

Motor Driver:

VCC is connected to 5V power supply of MCU,GND is connected to GND of MCU.

R_EN AND L_EN short circuit and input PWM signal for speed regulation

L_PWM,pin input 5V level,motor forward

R_PWM,pin input 5V level,motor reversal

1 | void setup() { |

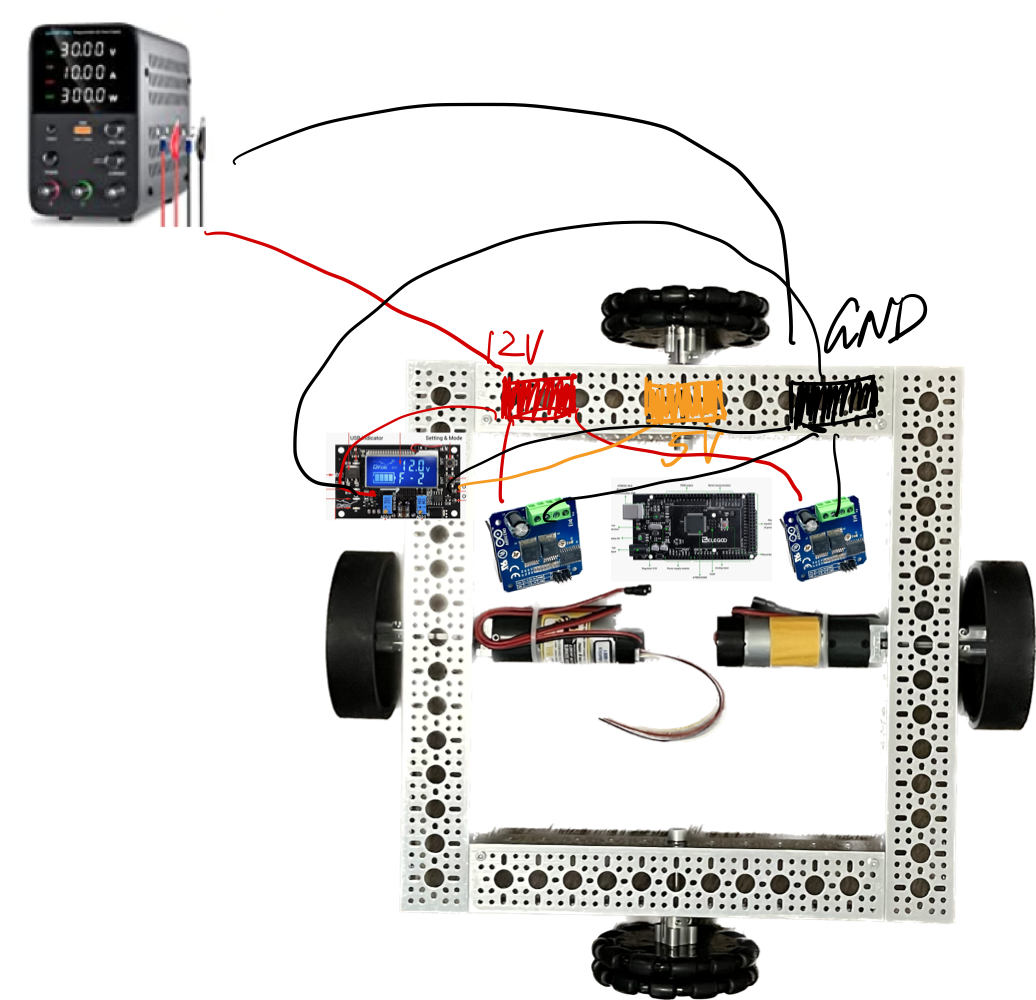

7.1. Update Dec.10

Currently the robot works great on open-loop rotate and move forward, backward

Next

- Close-loop control on the RPM

Test how linear the motor is. That is the relation between the PWM duty rate and the RPM

7.2. Update Dec.13

Re-organize the wire and hide the wire in the alumni channel

Currently the robot’s speed control is under PID control

To make the position control closed-loop, still need encoder+IMU

And localization system should be added (SLAM)

7.3. Update Dec.15

Use DC jack to power the Jetson and Arduino

Given the hardware and electronic elements I have, followed step

Arduino Remote ControlJetson useCommunicate with computerSetup wifi enable remote accessRead IMU dataInstall Lidar and read lidar data

7.4. Update Dec.17

Rewire the arduinoPower Arduino with Jetson NanoCommunicate between arduino and jetson nano

7.5. Update Dec.19

Add IR remote in arduino

TODO:

Remote control move forward/reverse/rotate- Use the lidar to build the map

7.6. Update Dec.21

Remote speed control and stop done

TODO:

- Add IMU

WireRead dataCalibrateStore offsetReload offset- 3D print a level for lidar

- SLAM

8. Takeout

Low frequency PWM would cause the motor hauling, by increasing the frequency (like 3k) the hauling would disappear. In some MCU, by playing with the register, we might change the default frequency.

While selecting the MCU, checkout how many interrupt are needed and how many interrupt can the MCU provide.

By using encoder’s both channel and both rising and falling, we can maximize the accuracy of the motor

A good motor is almost linear between RPM and PWM

When the code doesn’t go well, check the setting and setup

After rewiring, double check the position especially the pin number

While making the wire, the length or wire should be considered. It’s a system design, so leave some room for wiring but not too much