1. 1 Introduction

Premise: Know the means to calculate joint-position correspond to desired end-effector motions.

Problem: How to cause the manipulator acually to perform these desired motions.

Solution 1: Linear control system.

- In fact, non-linear is more usual, linear control is just a approximate methods

- It’s resonable to make such approximation, so lineat control methods are the ones most often used in industrial practice.

- Learn linear first is good for later study

2. 2 Control-Law Partitioning

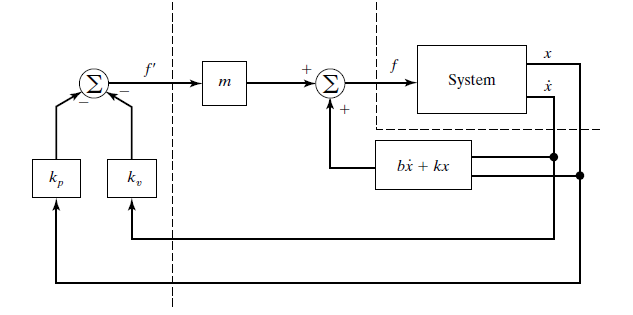

Partitioning Method (2 parts):

- model-based portion: make use of supposed knowledge of m,b,k, to make the system appear as a unit mass$\to$ servo portion simple.

- servo portion: make use of feedback to modify the behavior of the system

A open-loop equation of motion for the system:

$$

m \ddot { x } + b \dot { x } + k x = f

$$

The model-based portion of the control:

$$

f = \alpha f ^ { \prime } + \beta

$$

and we choose(because we want to make the )

$$

\begin{array} { l } { \alpha = m } \ { \beta = b \dot { x } + k x } \end{array}

$$

finally we get $\ddot { x } = f ^ { \prime }$

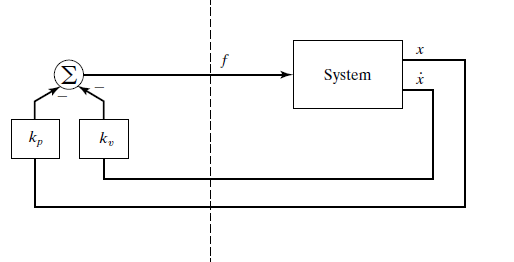

Graphiclly,we transform a system like this

into a system easier

What we need to do is design a control law to compute $f ^ { \prime } = - k _ { v } \dot { x } - k _ { p } x$

so it yields

$$

\ddot { x } + k _ { v } \dot { x } + k _ { p } x = 0

$$

2.1. Conclusion

- get the system‘s parameters

- find $\alpha ,\beta$

- calculate $k_v,k_p$ depend on the requirement

2.2. 3. Trajectory-Following Control

Know: trajectory, a funciton of time $x_d(t)$ and we can get $\dot x_d, \ddot x_d $as well

Define: $e=x_d-x$

Design $f ^ { \prime } = \ddot { x } _ { d } + k _ { v } \dot { e } + k _ { p } e$

Get: $\ddot { x } = \ddot { x } _ { d } + k _ { v } \dot { e } + k _ { p } e$

So, we can choose coefficients and design any response we want